In the northeast of the Netherlands, a company is leveraging its expertise in creating innovative plugs to enhance horticultural automation. Maan Group has intensified its focus on this area, leading to the establishment of Maan Horti Automation this year. As the company prepares for GreenTech Amsterdam, its director, Edwin Kruiper, shares the latest developments.

Showcasing the Latest Growcoon Dispenser

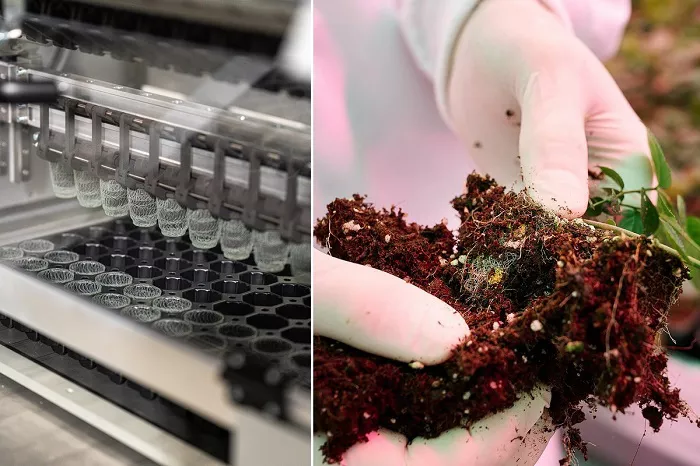

Maan Horti Automation plans to unveil the latest Growcoon Dispenser at the trade show. This machine will be demonstrated live for the first time at a shared booth with Klasmann-Deilmann, their partner and substrate supplier.

The new Growcoon Dispenser Advanced Series comprises two machines designed to place plugs in trays with unprecedented capacity and efficiency. Edwin explains, “The capacity we now offer is truly groundbreaking. We’ve increased our speed, surpassing what’s currently available on the market. This improvement is essential, as growers require high capacities to further automate and optimize their operations.”

The fully automatic variant of the Growcoon Dispenser Advanced Series can process over 55,000 Growcoons per hour, depending on the tray type, configuration, and specific conditions at the grower’s site. A Dutch grower and a North American grower have already tested the new machine.

During a visit in May, the machine was not yet in its GreenTech-ready state, allowing a glimpse of its interior workings. The setup resembles a fairground ride, but instead of people spinning around, Growcoons are swiftly and neatly placed into tray holes. The machine features mechanically controlled grippers that securely hold each Growcoon before placing them precisely into the tray compartments at an impressive rate of tens of thousands per hour.

Modular Machines for Progressive Automation

The Growcoon Dispenser Advanced Series is part of a full range of four machines that will soon be available, each facilitating further automation. There is a Basic line and an Advanced line. The Basic line dispenser uses a chute, while the Advanced line includes both a partially manual and a fully automatic variant. The fully automatic Advanced Growcoon Dispenser utilizes a pick-and-place principle and has been undergoing on-site testing since January to integrate seamlessly into existing automation processes.

At Maan Horti Automation, the decision was made to develop modular machines, allowing growers to progressively automate their operations. For instance, they can transition from a manual dispenser to a more advanced automated version. Edwin explains that by using similar sets of grippers, growers can scale up without needing additional investment in new grippers.

Biodegradable and Sustainable Plugs

The Growcoon is a versatile plug featuring an open net structure that promotes optimal root growth and fits well in trays. It is entirely PFAS-free and is designed to break down after its functional period, decomposing into carbon and water (C and H₂O). This decomposition process is TÜV-certified.

The speed of Growcoon’s breakdown depends on its composition. Currently, there are two recipes available, with two more set to be introduced this summer, according to Martine Huisman, Marketing Communication Specialist. “These additions offer options for a Growcoon that decomposes faster or, if desired, more slowly. There’s also a recipe in development for an even slower breakdown. This range of breakdown speeds ensures that growers can choose a Growcoon that decomposes according to their specific needs.”

Maan is gearing up for future demands, emphasizing sustainability and addressing labor challenges. For both the Growcoon and Nygaia—the plug and automation concept introduced at GreenTech last year—growers often choose the plug available from Klasmann-Deilmann, Edwin adds. “Afterward, they typically explore ways to optimize and automate the use of that plug.”

Looking Ahead

Maan Horti Automation sees significant opportunities for further automation in horticulture. Edwin envisions a future where trays filled with Growcoons emerge from machines completely loaded without an operator’s intervention. Currently, an operator is still necessary, but with the new machines, Maan Horti Automation is prepared to meet the growing demand from an increasing number of growers. They aim for the highest standards: maximum capacity, high performance, optimal control, and greater ease of use. Edwin states, “We’ve made a significant leap forward in speed and efficiency.”